Uniqueness of ESKAYEF Oncology Facility

The state-of-the-art facility of ESKAYEF Oncology has been developed by the technical collaboration with Telstar, A Europe-based global leader in providing life science solutions.

It is situated at Murapara, Rupganj , Narayangonj. The facility has the flexibility and capacity to undertake formulation, compounding and filling of a wide range of oncology products (such as liquid and lyophilized injectables, tablets and capsules).

Location at Rupganj

12,000 SFT production floor

Highly automated production lines

Compliance

This facility complies with all the stringent guidelines of global regulatory authorities like US FDA, UK MHRA, EU EMA, WHO GMP.

World Class Manufacturing Facility

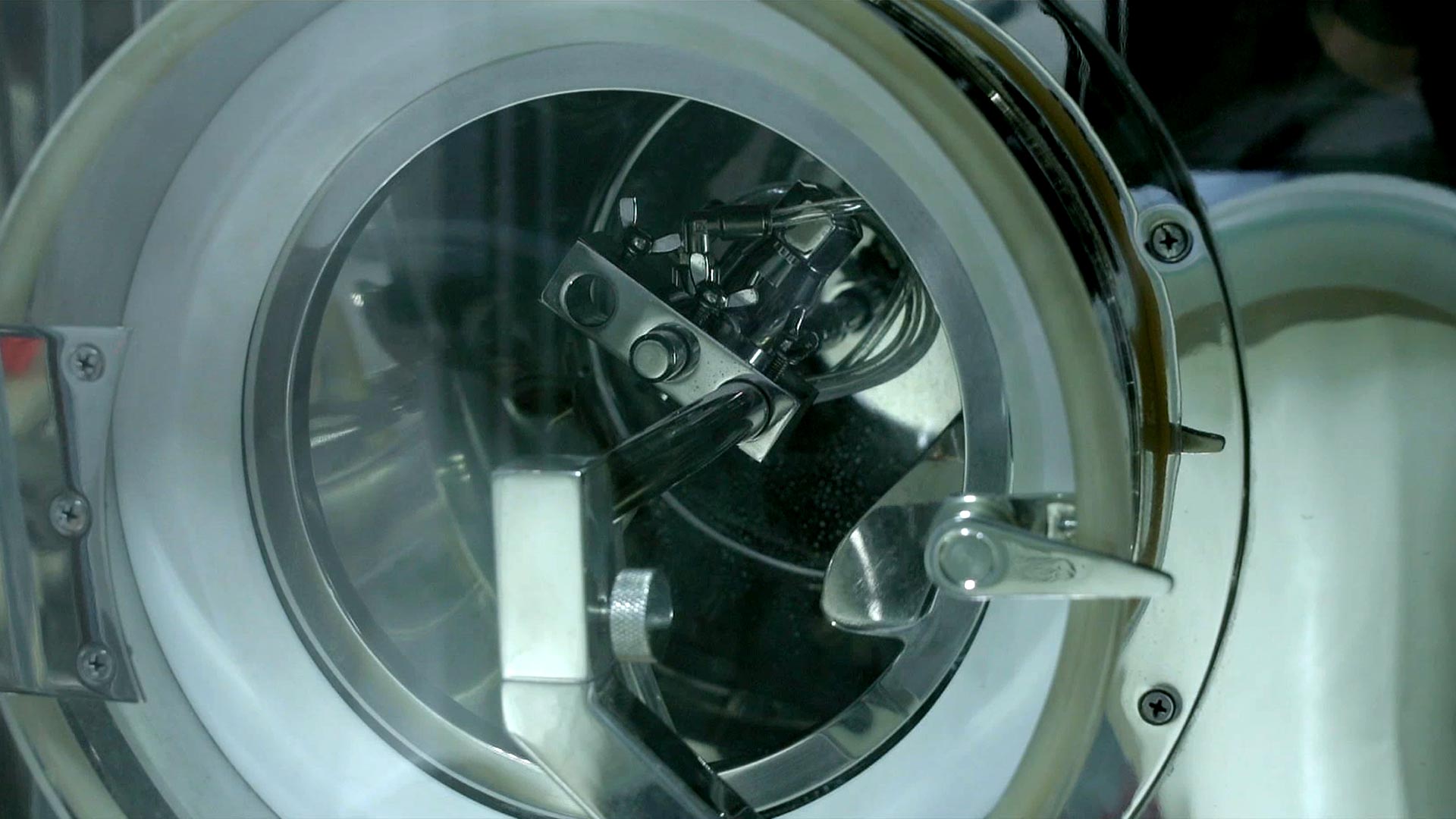

with Isolator Technology

Isolator technology has been applied in every step of manufacturing process of tablets, liquid injections and lyophilized Injections to ensure the safety of people and to avoid Cross Contamination of Oncology Products.

Unique Isolator Technology for Solid Dosage Form

Dispensing Isolator (Topleader, China)

Dispensing Isolator (Topleader, China)

Tablet Press (Telstar, UK)

Tablet Press (Telstar, UK)

Granulation Suite (Cosmec, Italy)

Granulation Suite (Cosmec, Italy)

Coating (Xiaolun, China)

Coating (Xiaolun, China)

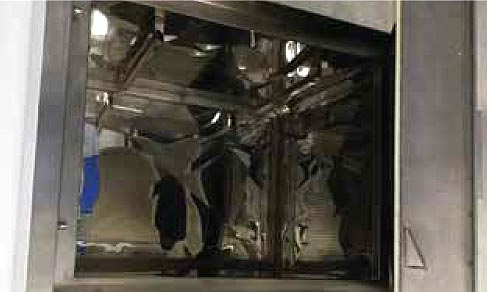

Unique Isolator Technology for Injectable Dosage Form

Sterile Liquid Filling

Sterile Liquid Filling

Autoclave

Autoclave

Lyophilizer

Lyophilizer

Dry Heat Sterilizer

Dry Heat Sterilizer

Injectable Dose

- Formulation Tanks

- Autoclave

- Dry Heat Sterilizer

- Vial Filling With Isolator

- Vial Wash External

- Lyophilizer

Oral Solid Dose

- Dispensing isolator

- Granulation Unit with isolator

- Tablet Compression with isolator

- Coating with isolator

OEL Validated Oncology Facility

OEL, or Occupational Exposure Limit is an upper limit of the acceptable concentration of a hazardous substance in workplace air.

First time in Bangladesh, Zero level of surrogate material was observed in breathing zone at working area of Eskayef Oncology plant. The controlled system and OEL performance test revealed, people working inside the facility is safe, even if they wear normal gown.

" Eskayef Oncology is the only company in Bangladesh and very few companies in the world, which successfully completed true OEL Validation as per ISPE (International Standard of pharmaceutical engineering).

"

PREMIUM QUALITY

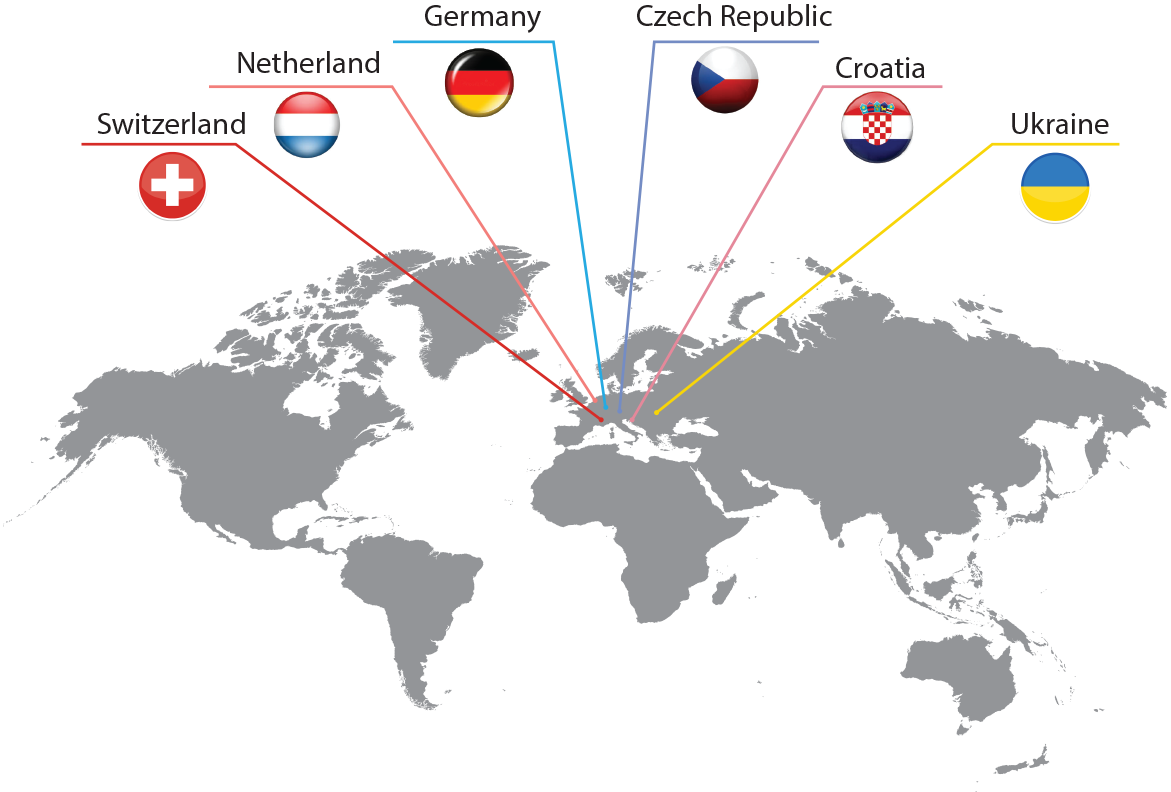

RAW MATERIALS FROM EUROPE

All the Raw Materials of ESKAYEF Oncology Products are sourced from different European countries.

COS* & US DMF* Grade API are used in ESKAYEF Oncology products.

Safety

To ensure occupational safety, Eskayef is the only company in Bangladesh to successfully complete true OEL (Occupational exposure limit) Validation as per ISPE. Some of the features are Pal in pal out is used for entry and exit which protects different work zones, Bubble and sink technique is used in airlock- prevents contamination, Delay timing interlock doors refreshes contaminated air, Dedicated water distribution ensures integrity of products and H14 HEPA filter is used in HVAC and exhaust that guarantees pure air.

GET IN TOUCH

For any information and assistance you may need, please send us your query and our team will get back to you.